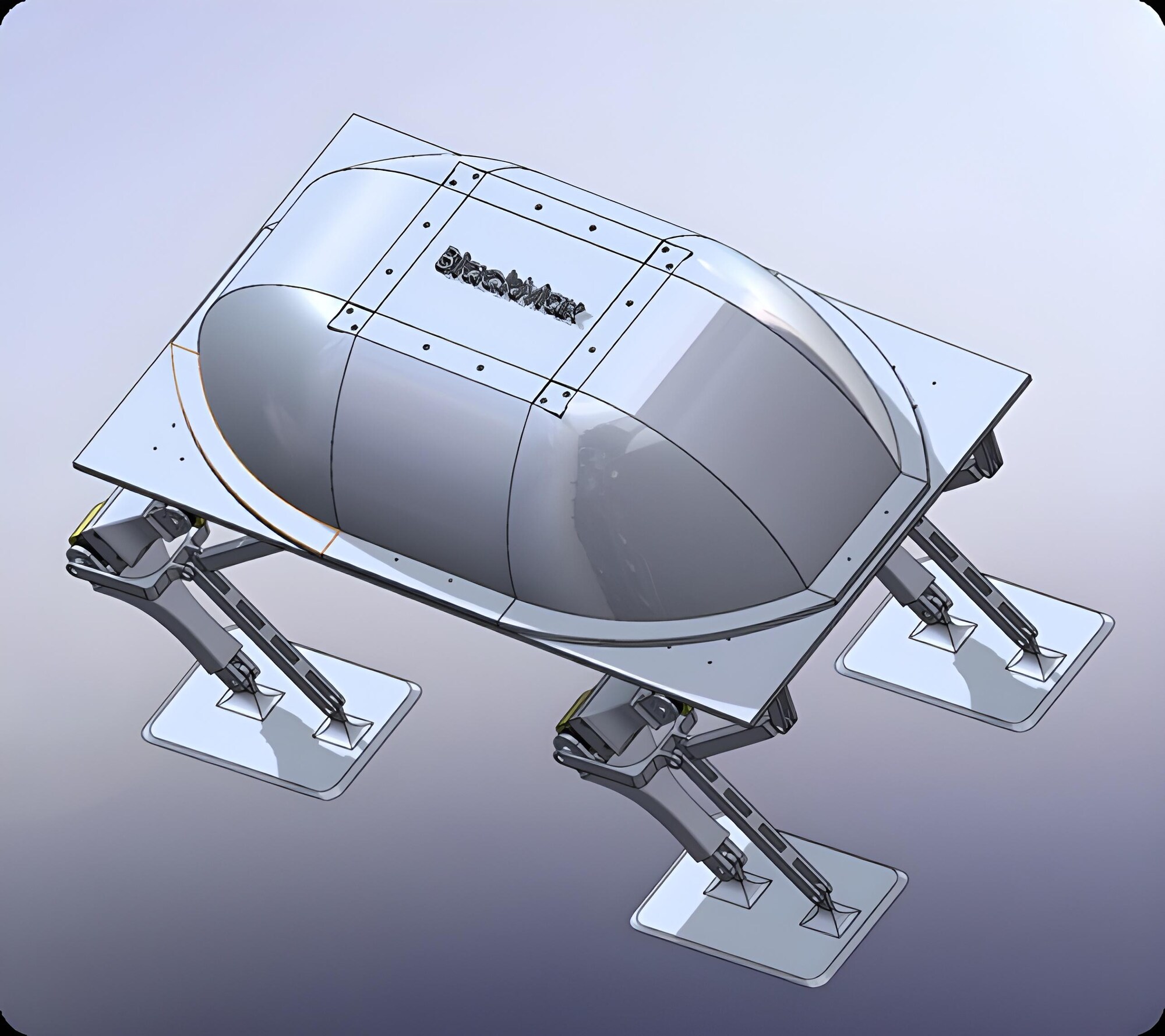

Meet BlackMax

BlackMax is designed with high-performance expectations in mind. Inspired by real-world motion, it walks on four legs powered by rotational joint motors—no wheels involved. Its sleek, all-black look hides a complex system of Raspberry Pi control, precision motors, and custom circuitry.

From initial sketches to full system integration, we built BlackMax through iterative prototyping:

We focused on real-world functionality. BlackMax is fully walkable and responds to movement commands with stable gait patterns. The final result? A responsive machine built from scratch—combining mechanics, electronics, and intelligent control.

Embedded Python/C++ control systems

BlackMax is driven by a hybrid Embedded Python and C++ control architecture, carefully engineered for real-time responsiveness and fine-grained control. The C++ layer manages low-level operations such as sensor data acquisition, motor control, and real-time actuation loops—ensuring millisecond-level precision and efficiency. On top of this, Embedded Python provides a flexible scripting environment for higher-level behavior programming, motion planning, and AI-based decision making.

Final assembly optimized for motion

In its final form, BlackMax is meticulously assembled for peak mobility and mechanical efficiency. Every joint, actuator, and linkage is precision-aligned to minimize friction and maximize responsiveness. The modular servo architecture ensures smooth articulation across all four limbs, while reinforced pivot points allow for high-torque maneuvers without compromising stability.